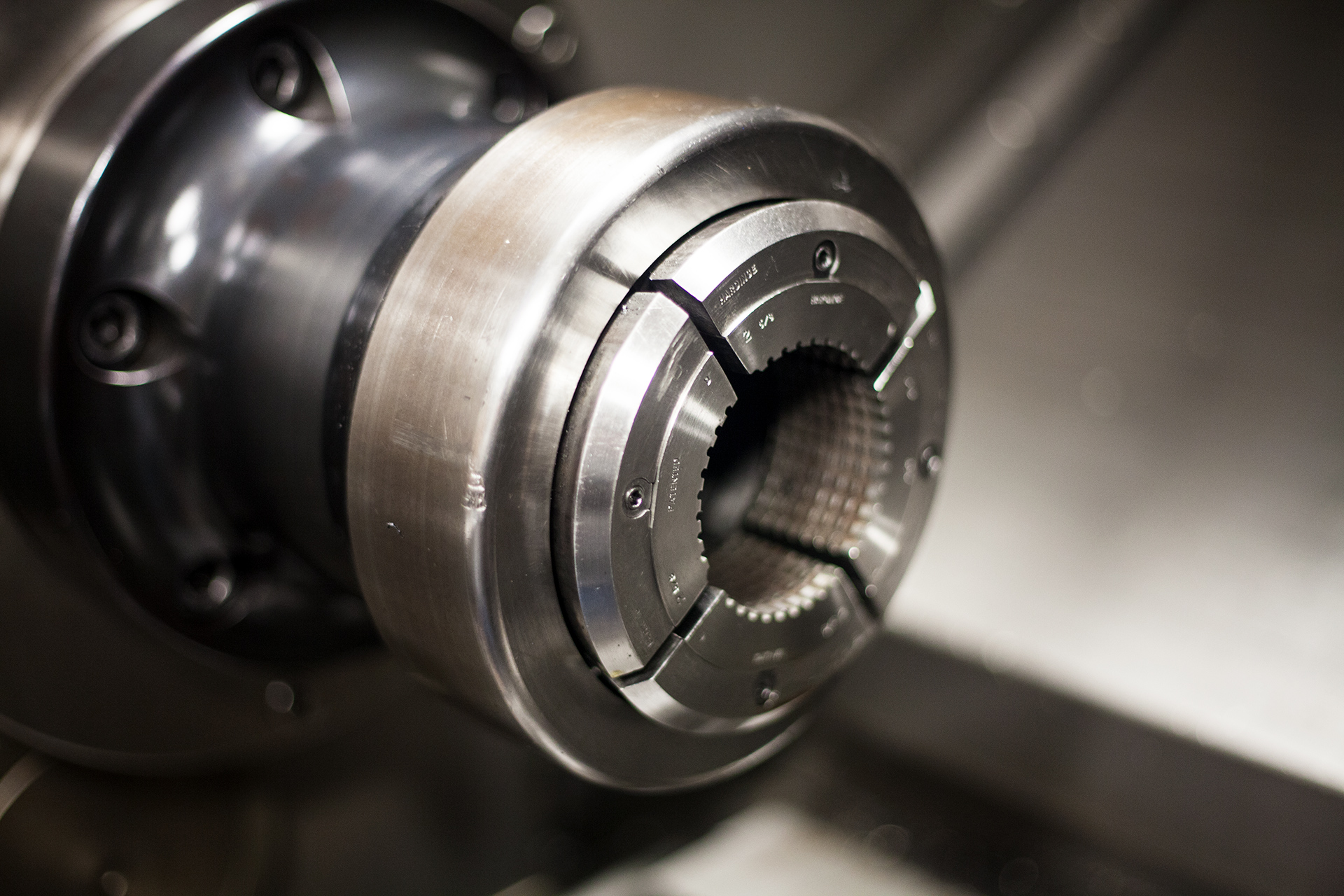

CNC Mill Turn Lathes

-

Okuma LU 45-M

This machine center has live spindles for secondary operations like milling, drilling, and tapping. This can eliminate separate operations and give higher productivity and accuracy. The spindles are a full rotary axis and have dual independent turrets.

Cutting Diameter 26"

Length 39"

Bar Capacity 4.5"

Milling Spindles 10HP

Main Drive 60HP

Chucks 15" & 20"

-

Okuma LC 40-M 2SC

This machine center has live spindles for secondary operations like milling, drilling, and tapping. This can eliminate separate operations and give higher productivity and accuracy. The spindles are a full rotary axis and have dual independent turrets.

Cutting Diameter 18.25"

Length 29"

Bar Capacity 3"

Milling Spindles 5HP

Main Drive 50HP

Chucks 12", 15", & 20"

-

Mori Seiki SL-6

Cutting Diameter 25.5"

Length 32"

Bar Capacity 3.5"

Milling Spindles 5HP

Main Drive 50HP

Chucks 15" & 20"

-

Mori Seiki NL 2500SY/700

Spindle 1

Chucks 10"

Collet 16C

RPM 6,000

Spindle 2

Chucks 8"

Collet 16C

RPM 6,000

Length 32"

Bar Capacity 0.5" - 3.1"

Max Turning Length 27.7"

X-Travel 10.2"

Y-Travel +/- 2.0"

Z-Travel 31.3"

Spindle 2 Travel 28.9"

-

Mori Seiki NL 2000Y/500

Spindle

Chuck 8"

Collets 16C or 25C

RPM 6,000

Bar Capacity 0.5" - 2.5"

X-Travel 10.2"

Y-Travel +/- 2.0"

Z-Travel 23.2"

Tailstock Yes

-

Mori Seiki NL 3000Y/3000

These Mori Seiki NL Mill-Turn Lathes have an additional Y axis that can be used to hold keyway width tolerances, and mill, drill, and/or tap bolt patterns and other features on the sides or ends of parts. They are also capable of polygon turning and hobbing small gear teeth.

Spindle

Chuck 15"

Collets 16C or 25C

RPM 6,000

Bar Capacity 3.5"

Max Turning Length 122.9"

X-Travel 11"

Y-Travel +/- 2.4"

Z-Travel 124.8"

Steady Rest Capacity 13.78"

Tailstock Yes

-

Mori Seiki CL-25

We have 2 of these machine centers in our shop.

Bar Capacity 3.5"

Cutting Diameters 17.7"

Steady Rest Capacity 12"

-

Okuma LB-15 II

Bar Capacity 2"

Cutting Diameters 9.8"

Length 39"

RPM 4,500

CNC Horizontal Mills

-

Hass EC-1600

X-Axis Travel 64"

Y-Axis Travel 40"

Z-Axis Travel 32"

Full Rotary Axis 30" Diameter

Table Capacity 10,000lb.

Tool Changer Capacity 50

High-torque 30 HP, #50 taper Spindle

High-Pressure through-spindle coolant

Full Part & Tool Probing

CNC Vertical Mills

-

Fadal VMC 5020A

Table Size 48" (X) x 20" (Y)

X-Axis Travel 50"

Y-Axis Travel 20"

Z-Axis Travel 28"

Through-spindle coolant

Temperature Controlled Spindle & Ballscrews

Additional Shop Equipment

-

Do-All Automatic Band Saw

-

Engine Lathe

-

Lagun Mill with Digital Readout

-

Sunnen Hone

-

Drill Presses

-

Cranes

-

Fork Lift

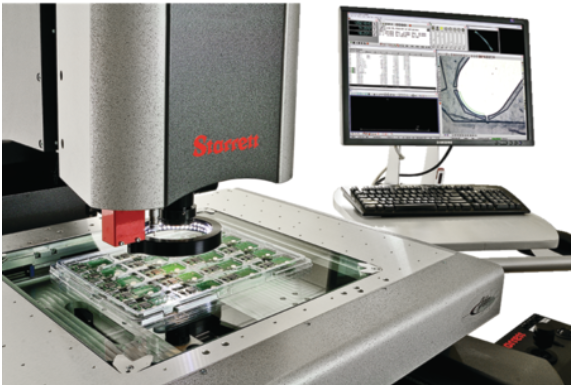

Measuring and Inspection Equipment

-

We have a large assortment of calibrated micrometers, bore gages, calipers, gage blocks and other precision measuring equipment.

-

We have a large assortment of thread gages and gage pins that are verified before each use.

FARO Arm

Mitutoyo CMM

Starrett Vision System

Control & Scheduling Systems

-

Realtrac real-time shop floor control and scheduling system

-

Cimnet DNC Plus direct numerical control system connected to all CNC machines

-

Applicon and Mastercam Computer Aided Design and Manufacturing System with shop floor terminals.

-

Programming with MasterCam and CAPS.